Candidate: Dimitri Oliveira e Silva

Program: UFSC / POSMEC

Date: March, 2023

Advisor: Victor Juliano De Negri (UFSC)

Co-advisor: Gierri Waltrich (UFSC)

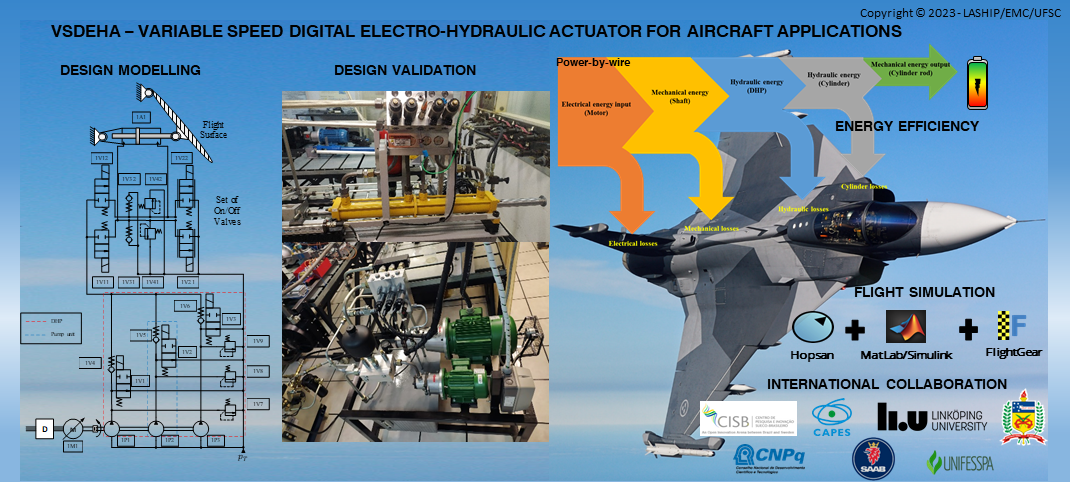

Abstract: The development of more efficient equipment, products, and systems is one of the main focuses of research today. In most cases, the study to obtain more efficient systems is related to reducing fuel consumption and reducing the emission of pollutants, as it occurs in the currently used means of transport, whether land, water, or air. Fluid power is a technology extensively used in industrial sectors, heavy machinery, and actuation systems for controlling aircraft surfaces. This technology stands out for its high power density, robustness, reliability, and dynamics. However, it is also known for its relative low energy efficiency, mainly due to the use of dissipative control and internal leakage in components. One of the ways to improve the energy efficiency of a system is to reduce energy waste. In this sense, digital hydraulics has been studied in recent years in order to reduce the use of dissipative control, widely used in hydraulic systems controlled by servo valves or proportional valves. This doctoral thesis proposes a new digital hydraulic actuator topology called Variable Speed Digital ElectroHydraulic Actuator – VSDEHA, with emphasis on application to aircraft control surfaces and was carried out in collaboration with the Linköping University and Saab AB. The proposed solution uses a digital hydraulic pump coupled to a variablespeed electric motor to supply a symmetrical cylinder, according to the flow demand. Through the use of the concept of digital hydraulics, the cylinder position control is carried out using the seat on/off valves, in order to avoid throttling control and internal leakage. A method for designing a variablespeed digital hydraulic pump is proposed. The application of the method generates useful information for the selection of electric motors, such as torque and speed, in addition to the suggested combination of pumping units to meet each actuator operating point. The use of the variable rotational frequency enables a smoother and more continuous control of the cylinder, presenting a good response to the position control. One of the advantages of this topology is the reduced number of valves, compared to other topologies of digital hydraulic actuators. The hydraulic system was implemented using MatLab/Simulink® and Hopsan software. An electric motor model was used to evaluate the energy consumption of the solution. Fuzzy logic was used to create an identifier of efforts and movement direction, used in the actuator control strategy. Experimental tests were performed on a test bench built for proof of concept. The energy evaluation carried out showed an efficiency of up to 58% in the conversion of hydraulic energy to useful energy output in the cylinder. Simulations were performed to compare the VSDEHA with other actuators. Compared to an electro hydrostatic actuator (EHA), it was possible to achieve twice the efficiency in converting hydraulic energy. Compared to a servo hydraulic actuator (SHA) in a flight simulation, the VSDEHA needed about 22 times less energy to perform the same work. Finally, it was concluded that VSDEHA has great potential for the development of more efficient hydraulic actuators with good controllability, and can also be applied in other areas such as industry and mobile machinery, with the advantage of using cheaper, simpler, and more robust components, reducing implementation and maintenance costs.

Reference: OLIVEIRA E SILVA, D. Variable Speed Digital Electro-Hydraulic Actuator for Aircraft Application. 2023, 211 p. Tese (Pós-Graduação em Engenharia de Mecânica) – Universidade Federal de Santa Catarina.